"Comprehensive Coating Services to Protect and Enhance Metal Components"

“At Corundum Coating and Innovation, we offer a full suite of job coating services tailored to protect and optimize the performance of metal components in diverse applications. Our expertise spans a variety of specialized processes, making us a one-stop solution for high-performance protective coatings.”

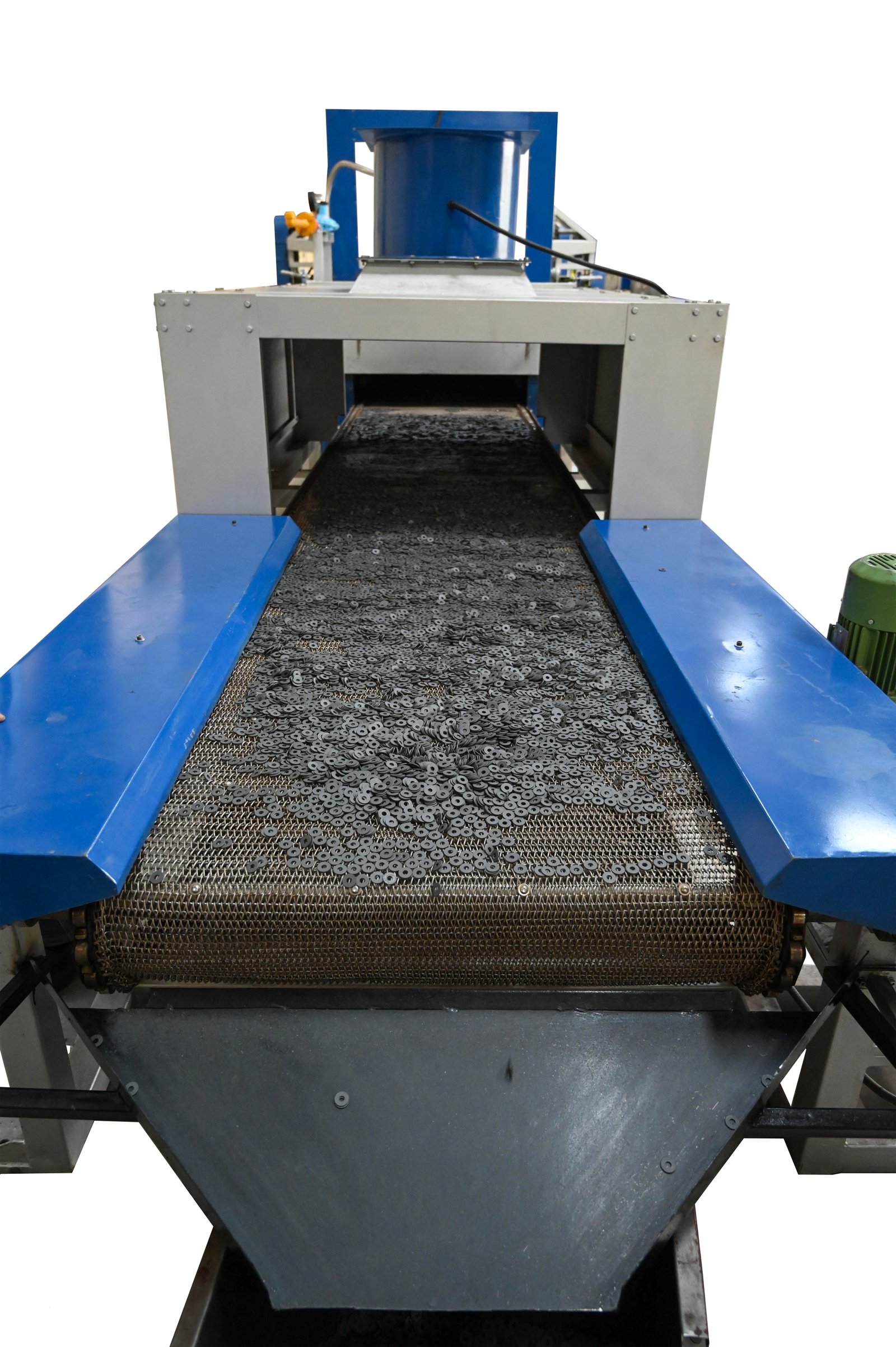

Zinc-Flake Coatings

Zinc-flake coatings are our speciality, providing exceptional corrosion resistance, durability, and environmental compliance. Our proprietary coatings, ECOMET Corundum and Ecoment Coat deliver superior performance for components used in demanding environments.

- Applications: Fasteners, bolts, automotive components, heavy machinery parts, and more.

- Key Benefits: Enhanced corrosion protection, high temperature resistance, and compliance with RoHS standards.

- Process: Dip-spin coating application for uniform, even coating coverage that meets precise thickness requirements.

Job Coating Services

Our comprehensive job coating services are designed to handle projects of any scale and complexity. We work with clients to provide customized solutions that meet their specifications, whether for high-volume production or small-batch jobs.

- Capabilities:Dip-spin application, flexible thickness customization, and a variety of finish options to meet diverse industry needs.

- Advantages:Scalable solutions, fast turnaround times, and precision quality control.

Surface Preparation and Pretreatment

Proper surface preparation is essential for effective coating application. We offer specialized pretreatment services to ensure optimal coating adhesion, durability, and longevity.

- Process Options:Includes degreasing and shot blasting to prepare surfaces, removing contaminants and ensuring a smooth, clean base.

- Quality Assurance:Our pretreatment stages are rigorously inspected to ensure surfaces are properly prepared for the coating process, maximizing performance and adherence

Quality Control and Testing

Quality is at the core of everything we do at Corundum Coating and Innovation. Our facility includes an advanced testing lab to ensure that each coating meets strict performance standards.

- Testing Services:Comprehensive Salt Spray Testing (SST), adhesion tests, coating thickness measurements, and chemical analysis for corrosion resistance.

- Quality Assurance Standards:Every project is subject to ISO-compliant quality protocols, with both in-process and final inspections to guarantee reliability.

High-Temperature and Corrosion-Resistant Coatings

Specialized coatings for components that must withstand harsh conditions and extreme temperatures. These coatings provide enhanced durability and protection for critical applications.

- Industries Served:Automotive, energy, marine, and construction.

- Performance Metrics:Resistance to rust, wear, and chemical exposure, ensuring components remain functional under demanding conditions.